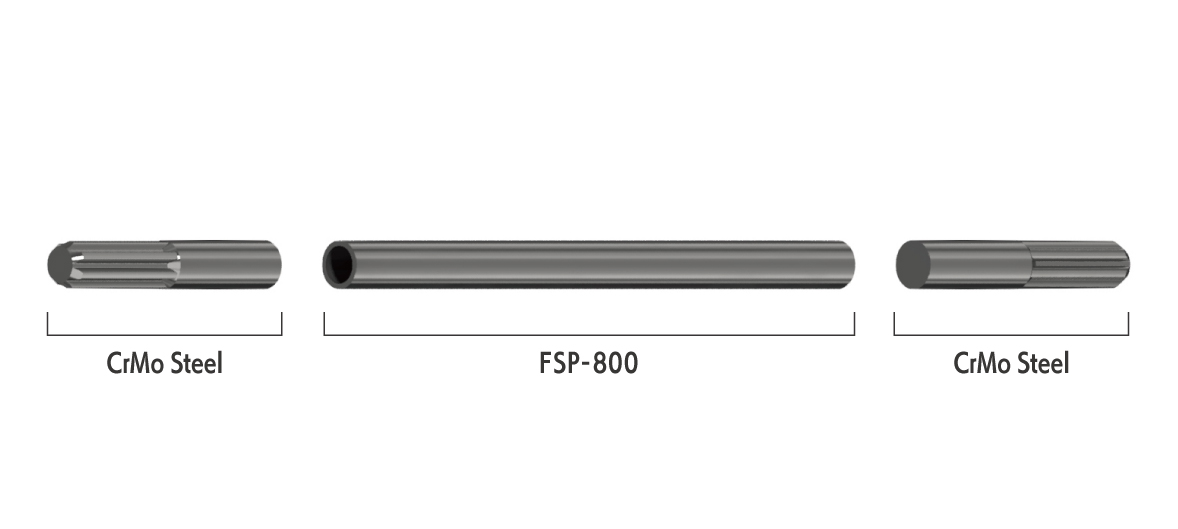

Heat treated chromium molybdenum steel adopters are attached on both ends of a center drive shaft to provide ultimate level of toughness and wear resistance.

The middle shaft, a light weight high strength steel FSP-800 sufficiently transfers the strong engine output without any power loss.

Strength to next level

All new 3 piece construction designed by FINE STEEL.

It was an enthusiastic challenge of the inventor who wanted to design

a high level though trimmers and brushcutters drive shaft.

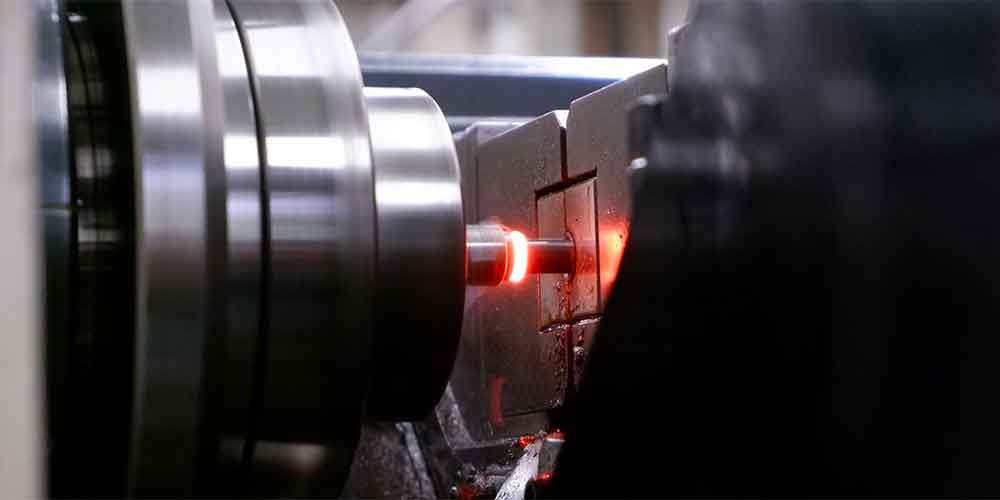

FSE's 3 piece construction drive design has been tested and quality guaranteed

with numerous prototype evaluation since 1990.

FSE's all new 3 piece construction overcomes a traditional drive shaft design

Vibration free trimmers and brushcutters drive shaft

New mechanical spring construction design reduces a level of amplitude of vibration caused by trimmers and brushcutters engine misfiring.

FSE also developed a new clutch drum as a similar vibration free component that to be built on trimmers and brushcutters engine.

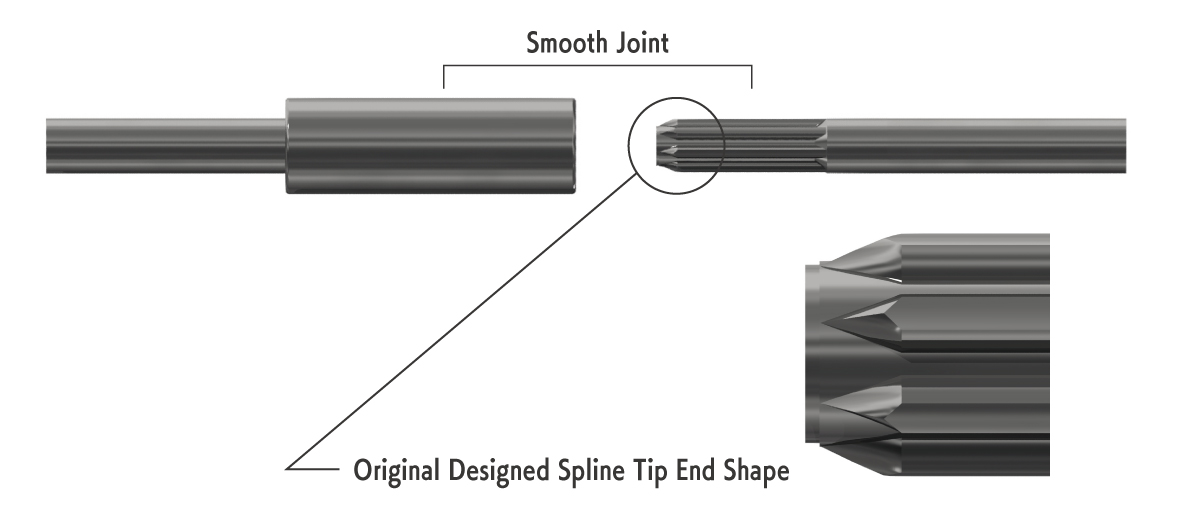

Smooth joint

FSE's 3 piece construction design allows a side end to have a transfer adopter directly attached to a main shaft.

This eliminates the excessive individual adopter piece and also functionally helps more smooth and direct drive feel of the unit to the operator.

Evolution

FSE's all new 3 piece construction ensures drive shaft component coaxially less than 0.1mm.

We provide the best solution with numerous material selection of attachment design and support your products with our cost reduction and manufacturing capability proposal.

Evolution never ends.